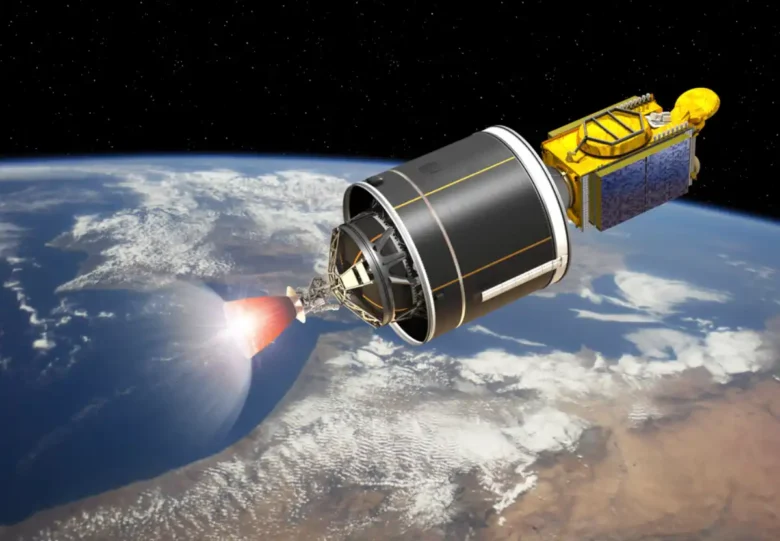

The European Space Agency (ESA) is testing a new way to make the Ariane 6 rocket carry more weight into orbit by replacing traditional metal fuel tanks with lighter carbon-fiber ones, a move that could increase payload capacity by up to two tonnes if the ongoing trials in Germany and France succeed.

The work is part of the Phoebus project, led by European space companies and research groups. The goal is to reduce the mass of the rocket’s upper stage so more room and weight can be used for satellites and space probes.

Most rockets today use metal tanks made from aluminum-based alloys. These tanks are strong but heavy. Carbon fiber weighs far less, which is why engineers are trying to apply it to tanks that hold super-cold liquids used as fuel. The challenge is that no one has ever flown a fully carbon-fiber tank for these liquids before. Liquid oxygen and liquid hydrogen must be stored at extreme cold. At those levels, even small material changes can cause cracks or leaks.

One of the main problem areas is the join between the carbon tank walls and the metal covers on each end. Metal shrinks more than carbon in deep cold. When they pull apart even slightly, gaps can form, and leaking oxygen can become very dangerous.

Engineers have spent years testing different seal materials and bonding methods to make sure the joint stays tight. In July 2025, the German company MT Aerospace started building the full-size end covers for the new oxygen tank.

The plan is to attach these covers before the end of the year and then fill the tank with liquid oxygen. Sensors will watch for any movement, cracking, or leaks during the deep-freeze tests. The Phoebus team is also changing the structure that carries the force of the engine. In a normal upper stage, a metal frame sits between the tanks and the engine, and separate pipes carry fuel.

In the new design, those pipes are part of the frame itself. They now help support the engine’s force while also moving fuel. Engineers create the centerpiece using 3D printing and then wrap carbon fiber around the pipe system. Assembly of this new structure is scheduled to begin in Bremen next year. If all goes to plan, it will be joined with the oxygen tank in 2026 for full ground testing.

Ariane 6 currently carries around 11.5 tonnes to a high Earth transfer orbit. By cutting the upper stage mass, engineers estimate they could add close to two tonnes of extra payload. That extra capacity could mean one more satellite on each launch or the ability to send heavier science missions into deep space.

Other rocket builders are watching the Phoebus project closely. Some already use carbon layers around metal tanks, but none have switched fully to carbon fiber for the main cryogenic tank structure.

The project began in 2019 as a research concept. Six years later, large parts are now being made in factories across Germany. If the upcoming cryogenic tests are successful, a full upper-stage model could be built and tested by 2028. If that phase also works, carbon-fiber tanks could become a standard design choice for future European launch vehicles, helping reduce costs and increase the amount of cargo each rocket can carry.

Source: Phoebus: framing carbon-fibre fuel tanks for maximum thrust